HANDLING & PACKING SOLUTION FOR

GRAIN, SPICES AND CONDIMENTS

Efficient handling and precise packaging are critical in preserving the quality, flavour, and shelf life of grains, spices, and condiments. Our handling and packing solutions are engineered for hygiene, speed, flexibility, and minimal human contact—ensuring your products stay fresh, safe, and market-ready.

Minimal Human Contact

Automated systems designed to reduce contamination risks and ensure product purity.

High Efficiency

Streamlined processes that maximize throughput while maintaining precision.

Product Integrity

Solutions that preserve aroma, flavor, and nutritional value from processing to packaging.

Material Handling Solutions

Grains & Pulses

- Automated intake hoppers, elevators, and conveyors

- Cleaning, grading, de-stoning, and magnetic separation

- Bulk silo storage with level monitoring

- Dust-free pneumatic conveying systems

Spices & Powders

- Hygienic screw conveyors and bucket elevators

- Specialized ribbon blenders for uniform mixing

- Vibratory feeders and sifters for flow control

- Advanced dust extraction systems

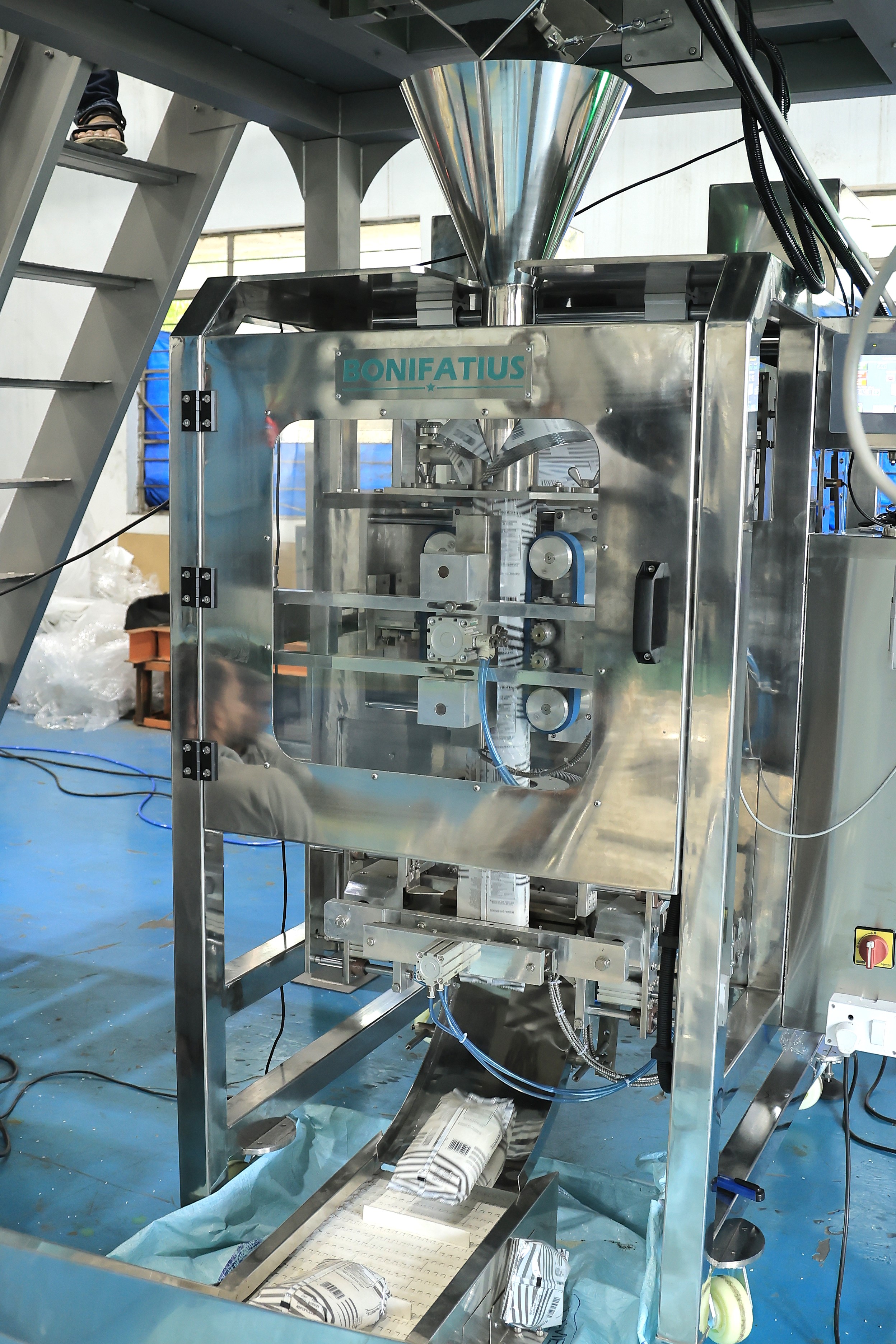

Packing Solutions

- Weighing and packing into pouches, sacks, or bulk bags

- Fully automatic FFS (Form-Fill-Seal) machines

- Vacuum or nitrogen-flushed pouch packing

- High-accuracy auger fillers for powders

Packing Solutions

Bulk Packaging

- Automated bagging systems (10kg-50kg)

- FIBC (big bag) filling stations

- Palletizing and stretch wrapping

- Moisture barrier liners

- Barcode tracking integration

Retail Packaging

- High-speed FFS (Form-Fill-Seal) machines

- Vacuum and gas-flushed packaging

- Precision auger fillers for powders

- Automatic cartoning systems

- Tamper-evident sealing options

Premium Packaging

- Jar filling and capping lines

- Blister packaging for portion control

- Custom sachet and stick pack machines

- Nitrogen flushing for extended shelf life

- Premium labeling and sleeving

Key Benefits

Hygienic Processing

Minimized contamination risks through reduced human contact and sanitary design

Precision Handling

Accurate portioning and gentle product treatment to maintain quality

Flexible Systems

Quick changeover between products and pack sizes for diverse SKUs

Enhanced Efficiency

High-speed automation that reduces labor costs and increases output

Extended Shelf Life

Specialized packaging that preserves freshness and aroma longer

Traceability

Integrated tracking systems for quality control and supply chain visibility