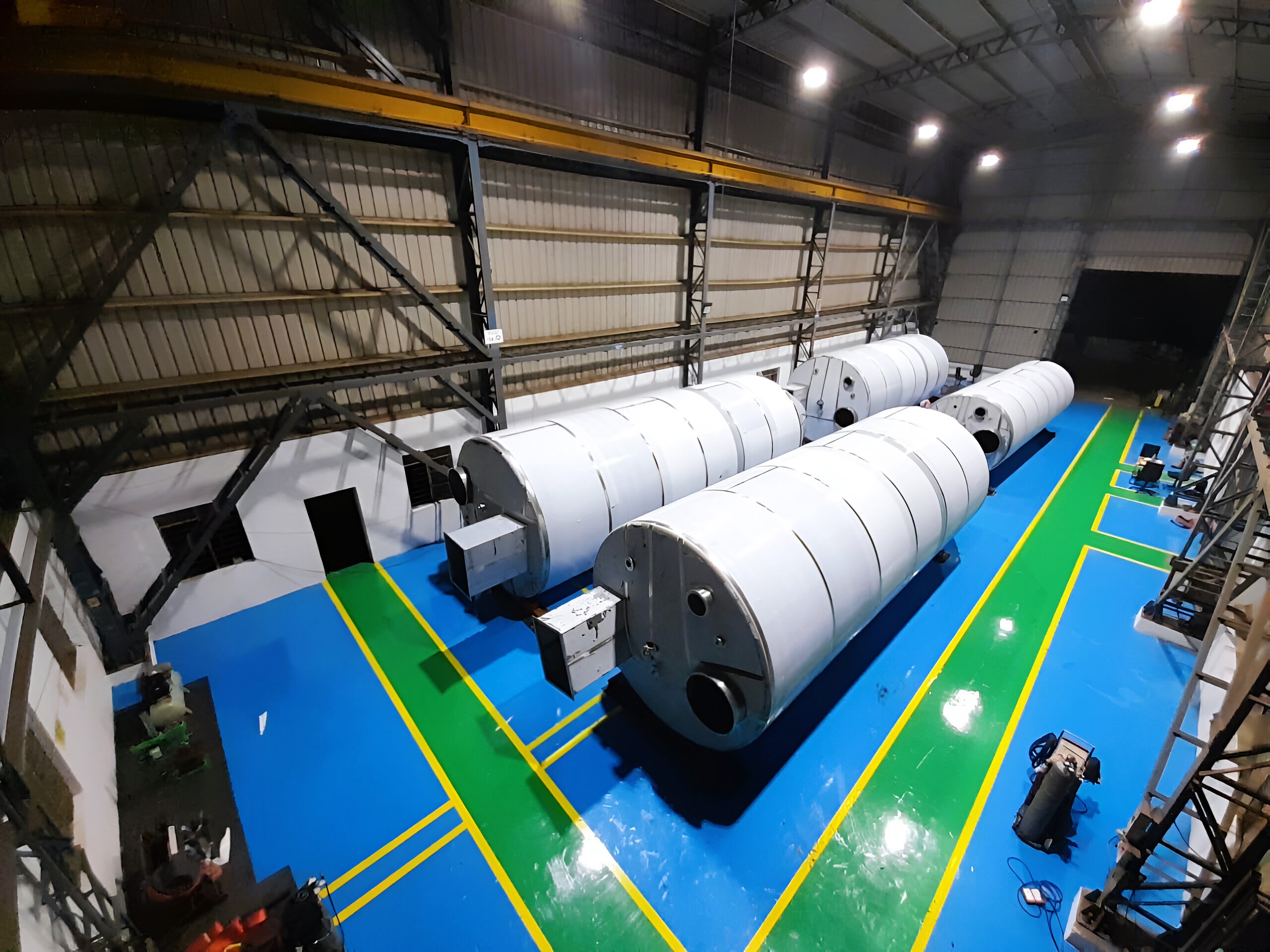

A DEDICATED FABRICATION UNIT IS THE HEART OF ANY PROCESS ENGINEERING COMPANY SOLUTIONS

It enables the in-house manufacturing of high-quality, custom-built equipment that supports hygiene, efficiency, and compliance across the food and beverage industry.

Our Fabrication Capabilities

🛠️ Custom Equipment Fabrication

- Stainless steel processing tanks, vessels, and silos (SS304/SS316)

- Skid-mounted processing units and modular systems

- Fabrication of mixers, blenders, fermenters, and reactors

🚿 Hygienic Piping & Structures

- Food-grade piping networks with sanitary fittings and valves

- CIP/SIP-compatible systems for dairy and beverages

- Fabricated utility piping for steam, air, RO, chilled/brine water

🏗️ Plant Infrastructure Support

- Fabricated platforms, service mezzanines, support frames, and walkways

- Conveyor systems, packaging tables, and operator stations

- Dust-free enclosures and partitions for spice, grain & bakery areas

🚚 Material Handling Systems

- Fabrication of screw conveyors, elevators, hoppers, and bins

- Bulk handling silos and storage systems for grains and powders

- Customized augers, feeders, and pneumatic transfer lines

Why Our Fabrication Services?

Fully Integrated Facility

Design, fabrication, testing, and assembly under one roof

Customized & Scalable

Tailored solutions from pilot plants to large-scale projects

Experienced Workforce

Skilled fabricators, welders, engineers, and QA team

Quality Assured

Every component tested for durability, hygiene, and performance

On-Time Delivery

Streamlined workflows and project tracking systems

From Design to Commissioning — Tailored Solutions for Every Industry

Dairy

Milk chilling tanks, pasteurizers, cream separators, Bulk cooler, etc.

Beverages

Mixing tanks, storage tanks, syrup rooms, and dosing lines

Grains

Hoppers, bulk storage bins, elevators, dust collectors

Spices & Condiments

Spice roasting chambers, filling tank, powder tanks, sauce kettles

Bakery

Ingredient Silos, jacketed mixing tanks, icing storage vessels

Key Benefits

Hygienic Processing

Long-lasting, corrosion-resistant stainless-steel equipment

Precision Handling

Hygienic fabrication ensures food safety and quality

Flexible Systems

Modular designs for easy installation and maintenance

Enhanced Efficiency

Scalable to suit start-ups, SMEs, and large industrial plants