VFFS

(Vertical Form Fill Seal)

Machines

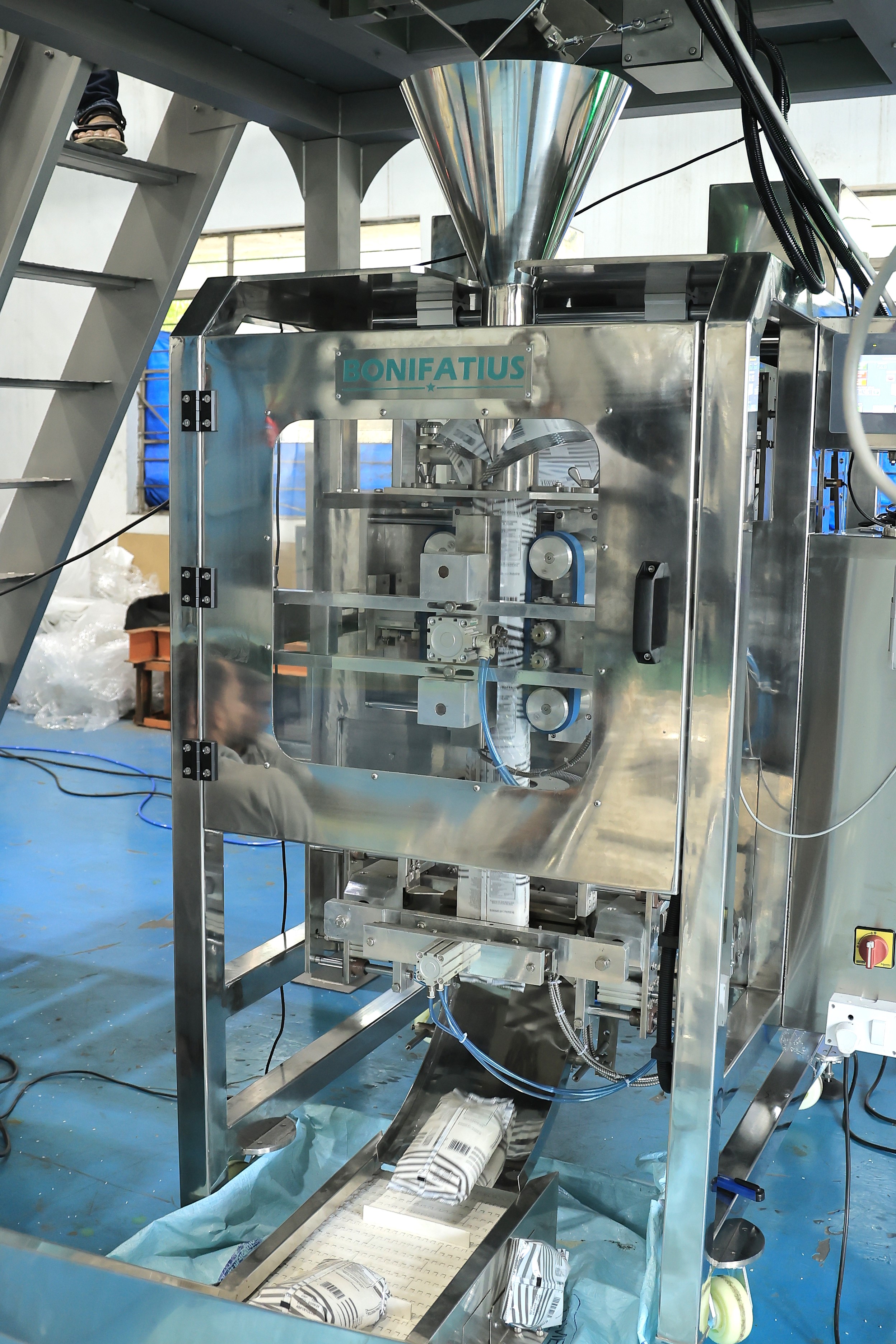

Are compact, automated packaging systems that form pouches from a film roll, fill them with product, and seal them—all in a vertical sequence. They are widely used across industries like dairy, food & beverages, bakery, grains, spices, and condiments for efficient, hygienic, and high-speed packing.

VFFS Pouch Packing Machines functions

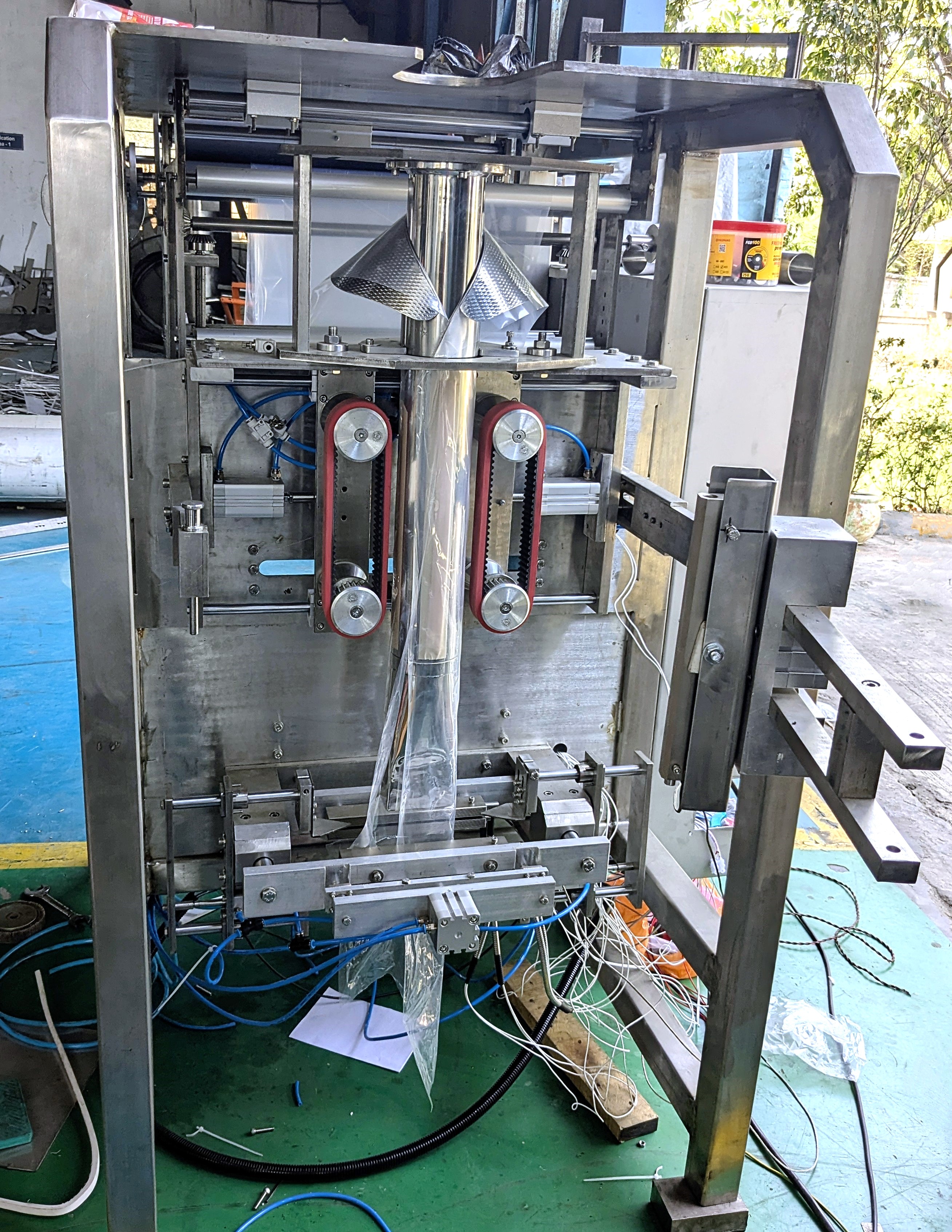

The VFFS bagger machine operates vertically and performs the following key functions in a continuous or intermittent motion:

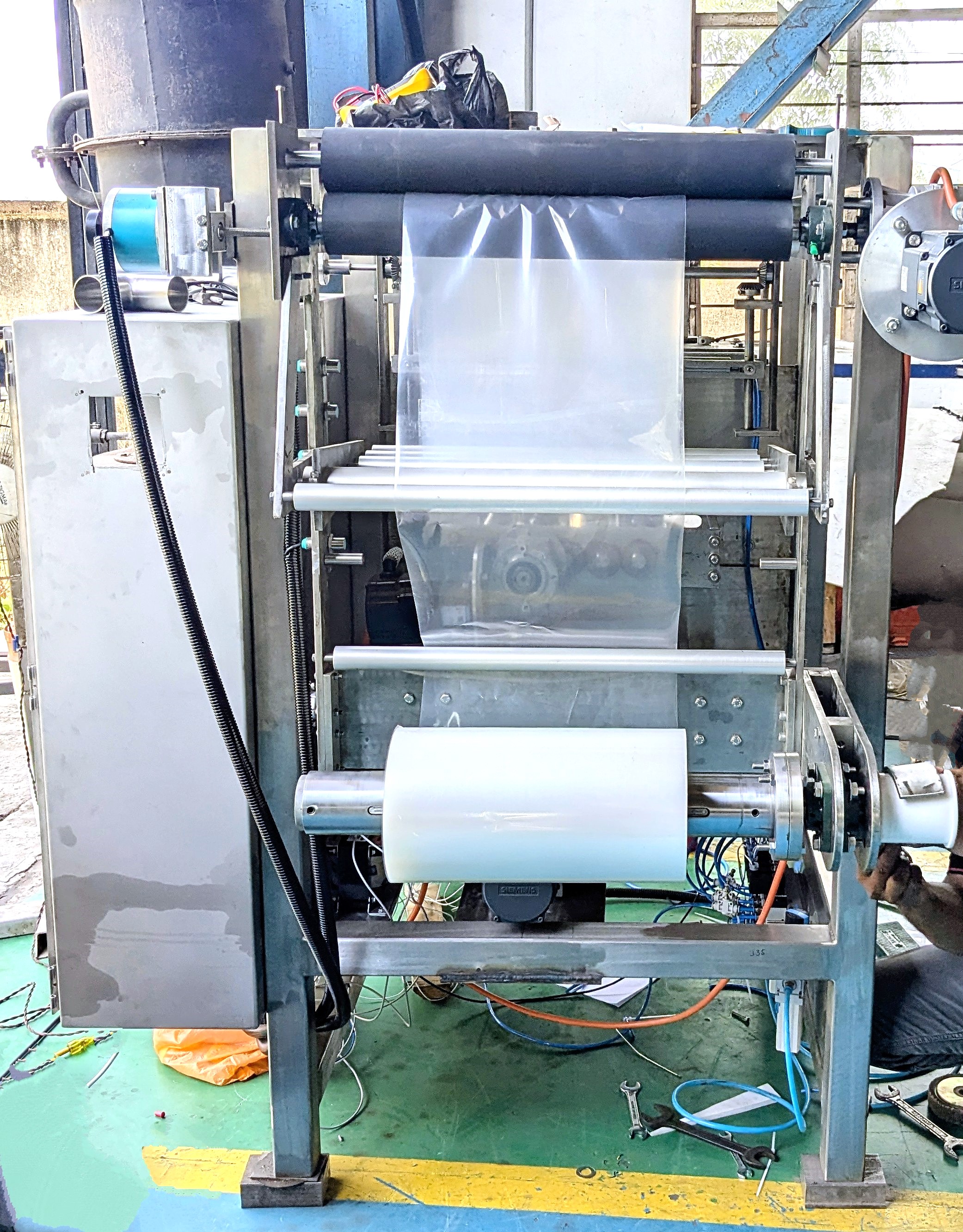

➦ Film Feeding and Forming: A roll of flat packaging film (typically plastic, laminate, or paper-based) is fed into the machine. The film is shaped into a tube around a forming collar and sealed along the vertical seam by heat sealing jaws.

➦ Product Filling: The formed tube is intermittently or continuously pulled down to a set length. As it moves, a dosing system (such as a multi-head weigher, auger filler, or volumetric cup filler) dispenses the correct amount of product into the tube through the hollow forming tube.

➦ Sealing and Cutting: The machine then seals the top of the filled bag (which also becomes the bottom seal of the next bag) and cuts it to separate the individual pouch. Seals are typically created using heat and pressure.

Types Available

Auger Filler VFFS

For fine powders

Weigh Filler VFFS / Multihead Weigher

For snacks and granules

Liquid VFFS

For sauces and beverages

Volumetric Cup Filler

For grains and sugar

Stick Pack (Multi-Lane)

For sachets and single-serve packs

Core Features

Form, Fill & Seal

Complete pouch creation and product filling in one cycle

High Speed

30–120 pouches per minute (Depends upon product, product density, weight & Numbers of heads)

Customizable Output

Pillow, gusseted, block-bottom, and sachet packs

Food-Grade Construction

Stainless steel body, easy to clean

Smart Control System

PLC with HMI touchscreen for quick changeovers

.jpg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)